9

SERVICE CENTRE –

LOCATIONS

– TECHNOLOGY & PRODUCT DEVELOPMENT – NEWS AND INFORMATION

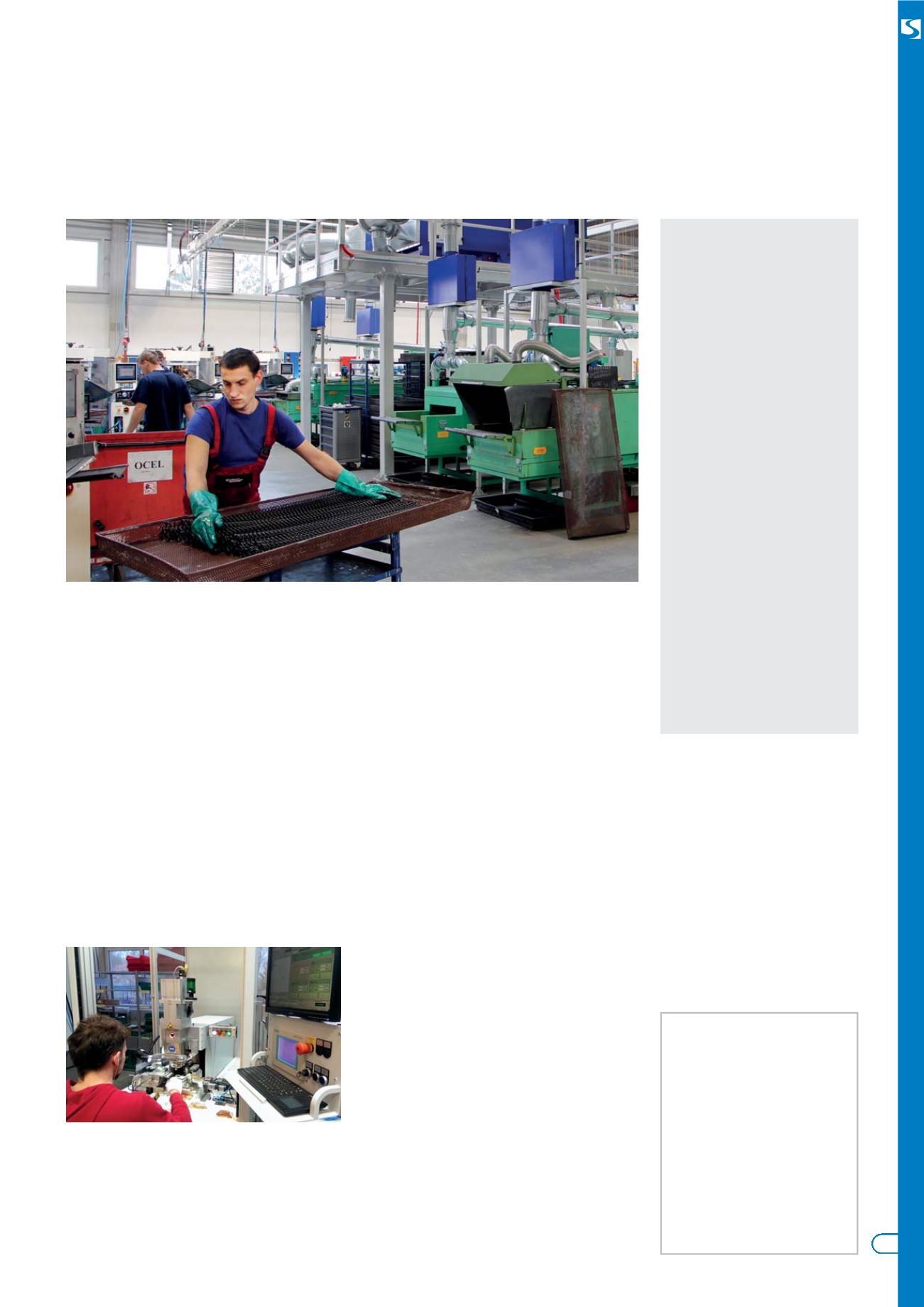

The production of traditional compres-

sion springs, which will continue to play

an important future role in Bor, has also

been restructured according to the prin-

ciple of continuous production. This ad-

ditionally provides the space required

to meet future demands of the market

by offering an even wider range of

products. All the processes from raw

material handling and machining to

storage of the end products in a mod-

ern flow-rack storage system are trans-

parent, traceable and extremely clean.

This also applies to the above-men-

tioned long compression springs, an

area in which the plant in Bor is partic-

ularly specialised. These components

demand high-level skills and knowl-

edge in terms of spring coiling, the nec-

essary quality parameters as well as

the coating and flocking. At the Group’s

Czech location, the extensive know-

how in valve production, which we re-

ported on in the last issue of

SCHERDELnews, has led to the devel-

opment of a special machine. This idea

has since been put into practice by the

SCHERDEL subsidiary AFEMA. To

date, nine of these innovative machines

have been built and are successfully in

use in Bor and at the manufacturing lo-

cation of SCHERDEL Sales & Technol-

ogy (SST) in the U.S. city of Muskegon.

It remains to mention that restructur-

ing of the plant in Bor also included

bringing the logistics up to the standard

of industry best practice. A new roofed

zone between the workshops ensures

the shortest possible routes for the de-

livery of raw materials and the collec-

tion of the finished products. Moreover,

the location now has its own shipping

department for supplying customers

worldwide.

(dk)

The editorial team of

SCHERDEL

news

looks for-

ward to your contribution.

Please send topic sugges-

tions, wishes or feedback

to:

or contact

Wolfgang Schelter on:

+49 9231 603-115

New methods are applied for manufacturing

electromobility components.

This image shows the production of the “long compression spring” for electric spindle drives.

Contact

Technické pružiny

SCHERDEL s.r.o.

Prúmyslovy aréal Vysocany

34802 Bor u Tachova

Czech Republic

Tel.: +420 374 702 111

Fax: +420 374 702 112

Contact persons

Markus Uhl, Manger of

Plant Technické pružiny

Tel.: +420 374 7021-22

Email: markus.uhl@

tps.scherdel.com

Dipl.Wirt.Ing (FH)

Stefan Barth, Manger of

Plant Technické pružiny

Tel.: +420 374 7021-14

Email: stefan.barth@

tps.scherdel.com

principle of continuous production

nsive structural work