rogressive thinking, innovativeness

and the enormous potential for de-

velopment within the Group are the rea-

sons why SCHERDEL is traditionally an

excellent partner for customers from

every sector, particularly the automotive

industry. A fact once again demonstrat-

ed by the company through an in-house

development. Cooperation with the two

SCHERDEL subsidiaries INNOTEC

GmbH and SIMENT GmbH, renowned

for their technical developments, and

specialists in the production of seat

components at the manufacturing loca-

tion in Marienberg resulted in a new

sensor for visual and acoustic seat belt

warning signals for vehicle passengers.

European consumer organisations have

been demanding and monitoring seat

belt reminders in cars since 2003, and

these devices are a key criterion when

rating a vehicle’s active safety equip-

ment. Today, almost every passenger

seat is equipped with a seat belt re-

minder. The special innovative element

of the SCHERDEL in-house develop-

ment is that the sensor is not installed,

as is normally the case, on the A-sur-

face of the seat foam beneath the trim,

but on the B-surface. This offers

greater creative freedom in terms of the

seat design. The foam, trim, seat heat-

ing and climate control can be config-

ured to offer much higher levels of seat-

ing comfort. The roots of seat sensors

can be traced back over 40 years to the

USA. At that time only about 15 percent

of all car drivers wore the available seat

belts. Working with legislators, the auto-

motive industry therefore introduced the

SBR sensor (seat belt reminder) to min-

imise the risk of injury to car occupants.

The requirements placed on the effi-

ciency of these sensors have continued

to grow over the years. Today, it is no

longer enough that a sensor simply

recognises a seat is occupied by a pas-

senger. Modern systems in the North

American market are able to classify a

respective person based on their weight

and can tell if only an object, like a

notebook or handbag, has been placed

on the passenger seat. SCHERDEL

started developing the new seat sensor

in 2010 and has since carried out vari-

ous tests in line with performance spec-

ifications together with its customers.

These include, amongst other things,

simulated driving situations and testing

based on temperature and rotational

load change rates. A wide range of

seats are tested, and the new

SCHERDEL SBR sensor can be ap-

plied for basic seats as well as for sport

and climate seats.

The evaluation unit retrieves data on

seat occupancy and the seat belt lock

on the passenger side. It works with a

sensing device that closes when a con-

tact is activated. This results in a

change of resistance, which in turn is

6

SERVICE CENTRE – LOCATIONS –

TECHNOLOGY & PRODUCT DEVELOPMENT

– NEWS AND INFORMATION

P

New sensor enhances seat

NEW PRODUCTS

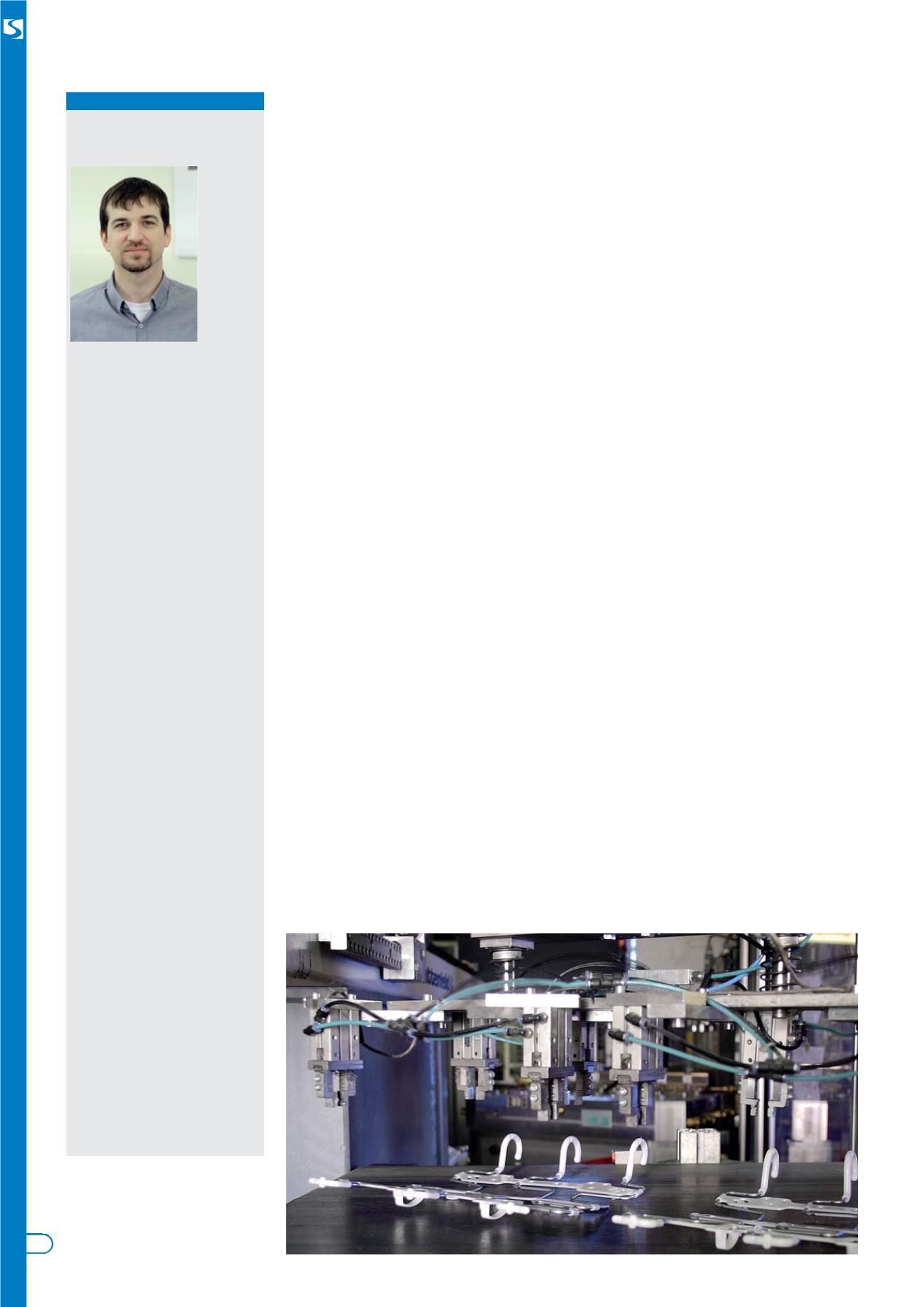

Large-scale production of SCHERDEL’s in-house

The production of vehicle seat mat

systems at the plant in Marienberg.

Staff profile

We’d like to introduce staff mem-

bers who will act as your contact

if required.

Dr.-Ing. Christian Konrad

Position: Materials Engineer /

SCHERDEL INNOTEC

Christian Konrad graduated

with honours from the Univer-

sity of Bayreuth in 2009.

Three years later, he obtained

his doctorate on “internal

oxidation in Ni-Zr-Y alloys”,

which was graded summa

cum laude, at the same insti-

tution. During his time at uni-

versity, Christian gained valu-

able experience at various

industrial firms throughout

Europe, and also carried out

research at the “University of

New South Wales” in Sydney

while completing his post-

graduate degree. In fact,

Christian still holds a teaching

position in metallic materials

at the UNSW.

Christian Konrad’s numerous

publications and applications

for patents pay testament to

his unique skill in his chosen

profession. Due to his exper-

tise in various scientific fields,

such as metallography, high-

temperature materials, elec-

tron microscopy and alloy de-

velopment, the German engi-

neer provides the Group as

well as partners and cus-

tomers with innovative re-

search and development

ideas.

In his free-time, the father-of-

two enjoys working with tim-

ber and metal, e.g. forging

Damascus steel.