detected by the electronics system that

ultimately outputs the seat belt re-

minder signal. A major challenge for the

developers was to find the ideal switch-

ing point in the entire seat across a

temperature range of minus 40°C to

plus 85°C whilst taking various tested

seat positions into account. The SBR

sensor has to ensure 100 percent de-

tection of objects weighing above 40 kg

and must not be activated below 5 kg.

The SCHERDEL in-house development

together with an appropriate vehicle

seat mat witnessed its first commercial

scale production run in September of

last year. The vehicle models of a

renowned manufacturer will be

equipped with the new technology from

mid-2015. The full assembly consists of

the ready-to-install and fully tested sen-

sor with a respective adapter. A com-

plete assembly line with end-of-line test

(EoL) has been set up in at the

SCHERDEL facility in Marienberg. To

facilitate traceability, each sensor

comes with a data matrix code. It is al-

so important to mention that

SCHERDEL has once again taken the

needs of customers into account by en-

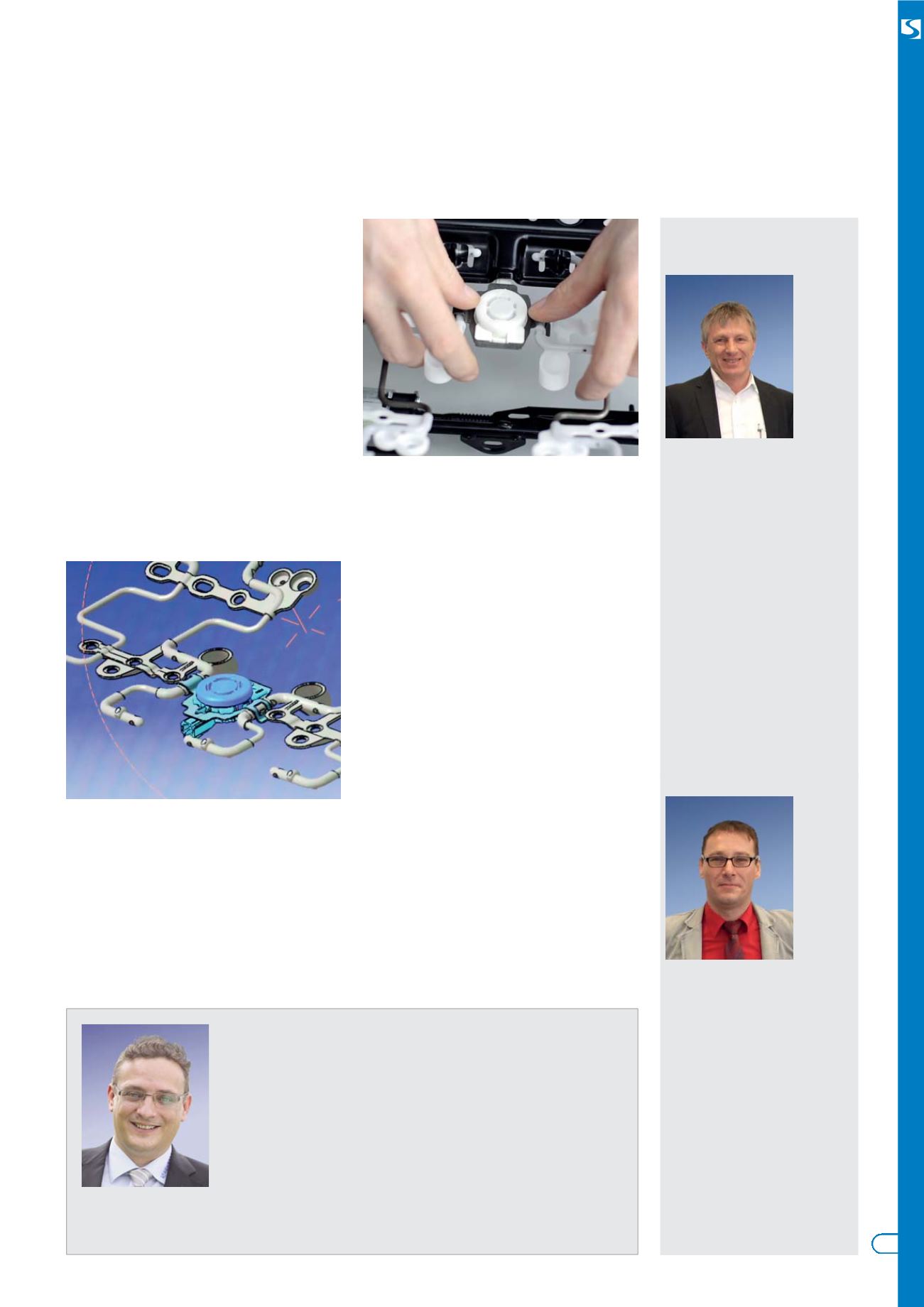

suring simple installation: It takes very

little effort and just a few seconds to

clip the sensor onto the spring mat and

fix it to the seat frame.

(dk)

7

SERVICE CENTRE – LOCATIONS –

TECHNOLOGY & PRODUCT DEVELOPMENT

– NEWS AND INFORMATION

The seat sensor is clipped onto the spring mat

quickly and easily.

The seat sensor is installed on the B-surface of

the foam, thus enhancing seating comfort.

Contact

SCHERDEL INNOTEC

Forschungs- und

Entwicklungs-GmbH

Scherdelstr. 2

95615 Marktredwitz

Germany

Tel.: +49 9231 603-0

Contact person

Michael Rankel

Tel.: +49 9231 603-612

Michael.Rankel@

scherdel.de

SCHERDEL

Marienberg GmbH

Am Federnwerk 1

09496 Marienberg

Germany

Tel.: +49 3735 710-0

Contact person

Dipl.-Ing. Jan Seitenglanz

Tel.: +49 3735 710 800

jan.seitenglanz@

fwm.scherdel.de

“The seat sensor developed in cooperation with our client

is a perfect example of how the demand for innovation of-

ten brings with it different ideas and different ways of look-

ing at problems. With this type of project it is always nec-

essary to rethink set positions and to evaluate previous ex-

periences from new perspectives and with fresh concepts.

Installation of the sensor on the B-surface of the foam

leads not only to new seat design options, but also signifi-

cantly improves seating comfort for the vehicle occupants.

A criterion that obviously has a huge impact on the suc-

cess of our development partnership in the market.”

Marcus Bach

Managing Director

SCHERDEL GmbH

comfort and safety

development for passenger seats