PRODUCTION

10

SERVICE CENTRE –

LOCATIONS

– TECHNOLOGY & PRODUCT DEVELOPMENT – NEWS AND INFORMATION

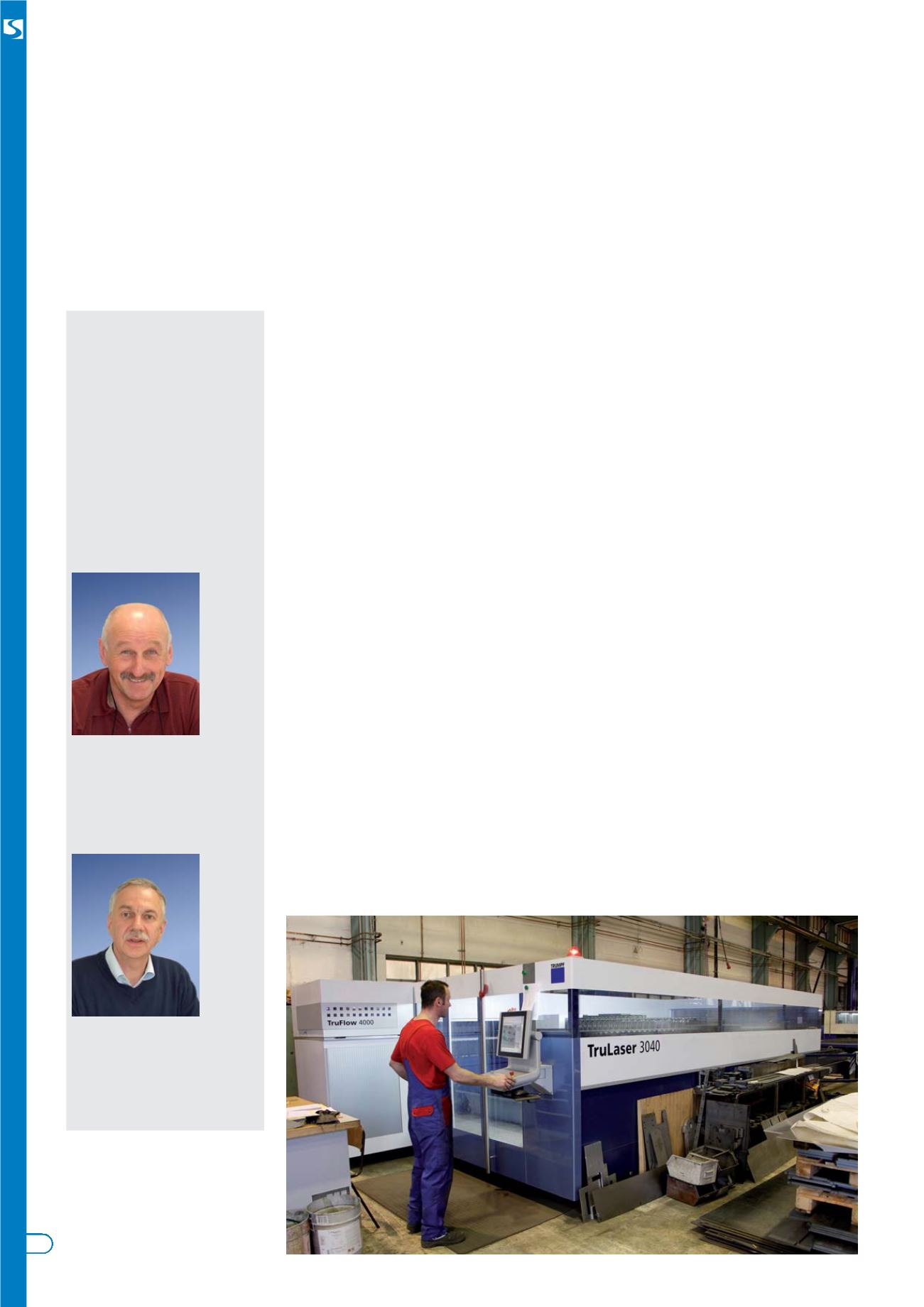

new state-of-the-art laser cutting

machine at the SCHERDEL sub-

sidiary Hamül Plauen allows the com-

pany to achieve higher standards of

precision and greater efficiency in the

field of mechanical engineering. A high

level of commitment from the staff en-

sured all customer orders were com-

pleted on schedule without delays dur-

ing the conversion phase. Clients also

profit from the higher economic efficien-

cy of the new machine: only one cutting

head is required for all sheet thickness-

es, and the high degree of automation

– e.g. when changing nozzles and

aligning beams – means set-up and

non-productive times are reduced to a

minimum.

As a steel processing specialist,

Hamül Plauen boasts an extensive

product portfolio, ranging from simple

components to intricate welded compo-

nents in single, small and large batch

production runs. High level flexibility is

therefore an essential pillar of produc-

tion to guarantee customer satisfaction.

This criterion is more than fulfilled by

the new laser cutting machine. It is de-

signed to exceed expectations through

outstanding laser power and an opti-

mised operating concept. For instance,

in conjunction with the overall dynamics

of the applied linear drive system, an

integrated pallet changer provides

faster sheet exchange and ensures

quick and reliable operation. A convey-

or belt for removing slag and small

parts reduces downtime for cleaning

and maintenance work. Enhanced soft-

ware functions enable optimum use of

materials while maintaining a continu-

ous high level of throughput. This obvi-

ously also raises efficiency standards

for secondary operations.

The roller and ball-raced flat runners

of the laser cutting machine accommo-

date two different drive models. The

maintenance-free, gearless torque drive

guarantees robust alignment of the X-

axis by producing a high torque output.

The aforementioned linear direct drive

is used for the Y and Z-axis and en-

ables ultra-precise and high-speed con-

trol of the laser unit. Maximum preci-

sion is guaranteed with the new laser

cutting machine thanks to exact spray-

ing of the piercing points to prevent

craters forming; something that can oc-

cur when processing thicker gauge

steel. The laser head is additionally fit-

New laser cutting machine

efficiency and precision

Hamül Plauen GmbH & Co. KG now processes var

one cutting head

A

A faster and more flexible workflow

is guaranteed by the new laser

cutting machine at Hamül in

Plauen. It significantly improves

production quality.

Contact

Hamül Maschinenbau

Plauen GmbH & Co. KG

Hans-Sachs-Str. 28

08525 Plauen

Germany

Tel.: +49 3741 599-20

Fax: +49 3741 599-26

Email:

Manager of Plant

Robert Bruischuetz

Tel.: +49 3741 599-22

Fax: +49 3741 599-30

Email:

Martin Loch

Tel.: +49 3741 599-23

Fax: +49 3741 599-26

Email: