Page 11 - SCHERDELnews 2/15e

P. 11

vehicle seats and backrests PRODUCTION PROCESSES – MECHANICAL ENGINEERING – TECHNOLOGY & PRODUCT DEVELOPMENT – NEWS AND INFORMATION

tube assembly for a modular seat – state-of-the-

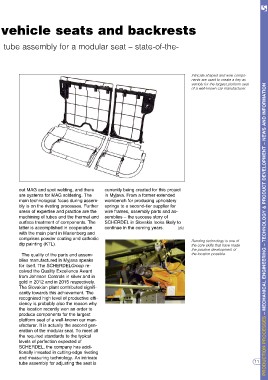

Intricate shaped and wire compo-

nents are used to create a key as-

sembly for the largest platform seat

of a well-known car manufacturer.

out MAG and spot welding, and there currently being created for this project

are systems for MAG soldering. The

main technological focus during assem- in Myjava. From a former extended

bly is on the riveting processes. Further

areas of expertise and practice are the workbench for producing upholstery

machining of tubes and the thermal and

surface treatment of components. The springs to a second-tier supplier for

latter is accomplished in cooperation

with the main plant in Marienberg and wire frames, assembly parts and as-

comprises powder coating and cathodic

dip painting (KTL). semblies – the success story of

SCHERDEL in Slovakia looks likely to

continue in the coming years. (dk)

The quality of the parts and assem- Bending technology is one of

blies manufactured in Myjava speaks the core skills that have made

for itself. The SCHERDELGroup re- the positive development of

ceived the Quality Excellence Award the location possible.

from Johnson Controls in silver and in

gold in 2012 and in 2015 respectively. 11

The Slovakian plant contributed signifi-

cantly towards this achievement. The

recognised high level of productive effi-

ciency is probably also the reason why

the location recently won an order to

produce components for the largest

platform seat of a well-known car man-

ufacturer. It is actually the second gen-

eration of the modular seat. To meet all

the required standards to the typical

levels of perfection expected of

SCHERDEL, the company has addi-

tionally invested in cutting-edge riveting

and measuring technology. An intricate

tube assembly for adjusting the seat is